Disassembling:

1. First, remove the engine from the bike frame and place it on a stable workbench.

2. Remove the clutch cover, clutch plates, and pressure plate from the engine.

3. Remove the crankshaft nut from the center of the crank disc using a suitable socket wrench.

4. Use a crankshaft puller to remove the crank disc from the crankshaft. If a puller is not available, tap the crank disc gently with a soft-faced hammer until it loosens from the crankshaft.

5. Once the crank disc is removed, inspect it for any signs of wear, damage, or cracking. If any of these issues are present, the crank disc should be replaced.

Assembling:

1. Install the new or reconditioned crank disc onto the crankshaft by aligning the keyway with the corresponding slot on the crankshaft. Use a crankshaft puller or a soft-faced hammer to gently tap the crank disc into place.

2. Install the crankshaft nut and tighten it to the manufacturer's specifications using a suitable torque wrench.

3. Reinstall the clutch plates, pressure plate, and clutch cover onto the engine.

4. Reinstall the engine onto the bike frame, making sure to reconnect any electrical or mechanical connections that were removed during the disassembly process.

5. Start the engine and test the clutch operation to ensure that the crank disc is properly installed and functioning correctly.

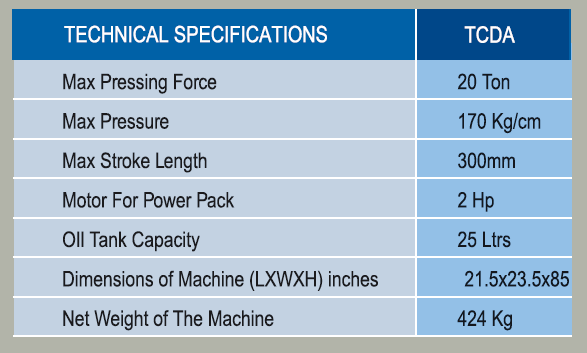

A specialized machine is used to assemble and disassemble the crank disc from the crankshaft. This machine is called a crankshaft puller, which is used to remove the crank disc from the crankshaft. The crankshaft puller uses a combination of pressure and force to pull the crank disc from the crankshaft without damaging either component.

In addition to the crankshaft puller, a torque wrench is also necessary to ensure that the crankshaft nut is tightened to the manufacturer's specifications. This is important because an improperly tightened crankshaft nut can cause the crank disc to loosen, resulting in engine damage or even complete failure.

Connecting Rods Boring Machine | Vertical Cylinder Fine Boring Machine | Line Boring Machine | Vertical Hydraulic Surface Grinding Machine | Two-wheeler crank disassembly and assembly Machine | Valve Seat Boring Machine |

Standard Automotive Machines (India) Pvt.Ltd

Automobile Engine Rebuilding Equipments, Machine Tools for Automobile Engine Rebuilding, Versatile Automotive

....

Products & Services