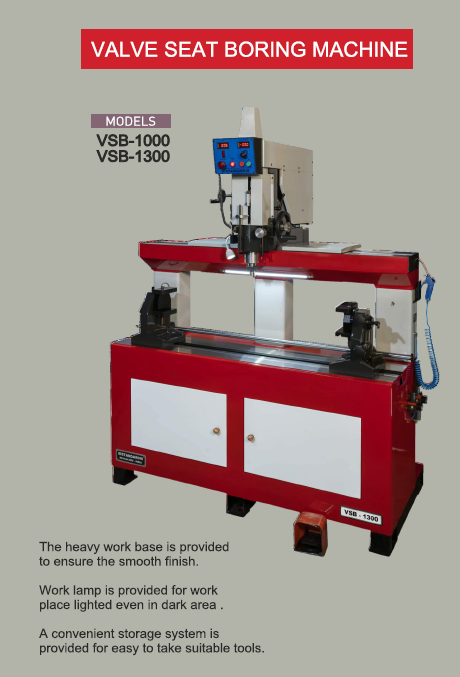

The valve seat boring machine typically consists of a base, a rotating spindle, and a cutting tool. The cylinder head is mounted onto the base, and the spindle is lowered into the cylinder head, where it rotates at high speed. The cutting tool is then used to remove material from the valve seat, creating a precise and smooth surface for the valve to seal against.

There are different types of valve seat boring machines available, including manual and automatic machines. Manual machines require the operator to manually control the cutting tool, while automatic machines use computerized controls to precisely cut the valve seats.

Valve seat boring machines are important tools for engine builders, as they allow them to ensure that the engine valves seat properly and seal tightly, which is crucial for engine performance and longevity.

Connecting Rods Boring Machine | Vertical Cylinder Fine Boring Machine | Line Boring Machine | Vertical Hydraulic Surface Grinding Machine | Two-wheeler crank disassembly and assembly Machine | Valve Seat Boring Machine |

Standard Automotive Machines (India) Pvt.Ltd

Automobile Engine Rebuilding Equipments, Machine Tools for Automobile Engine Rebuilding, Versatile Automotive

....

Products & Services